Product Description

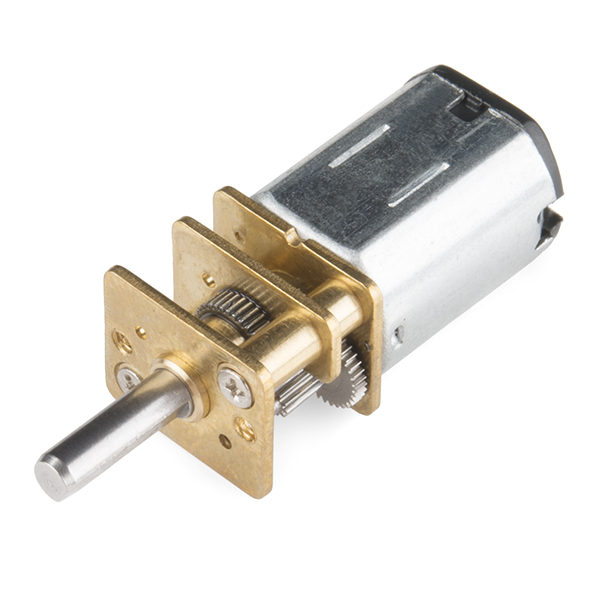

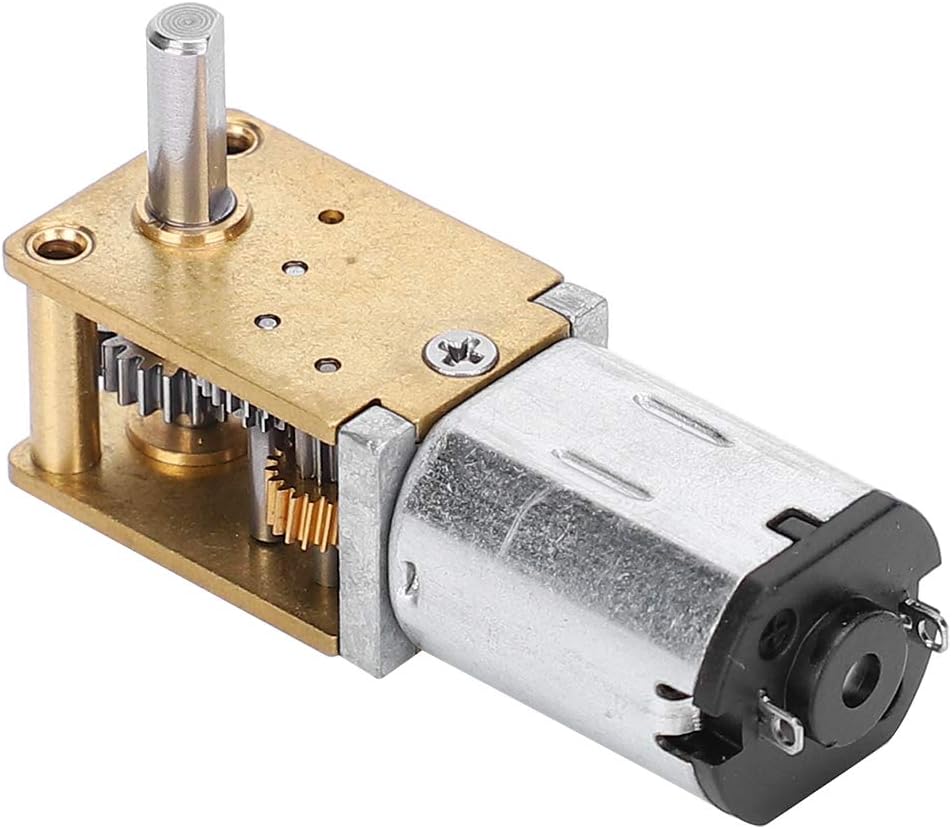

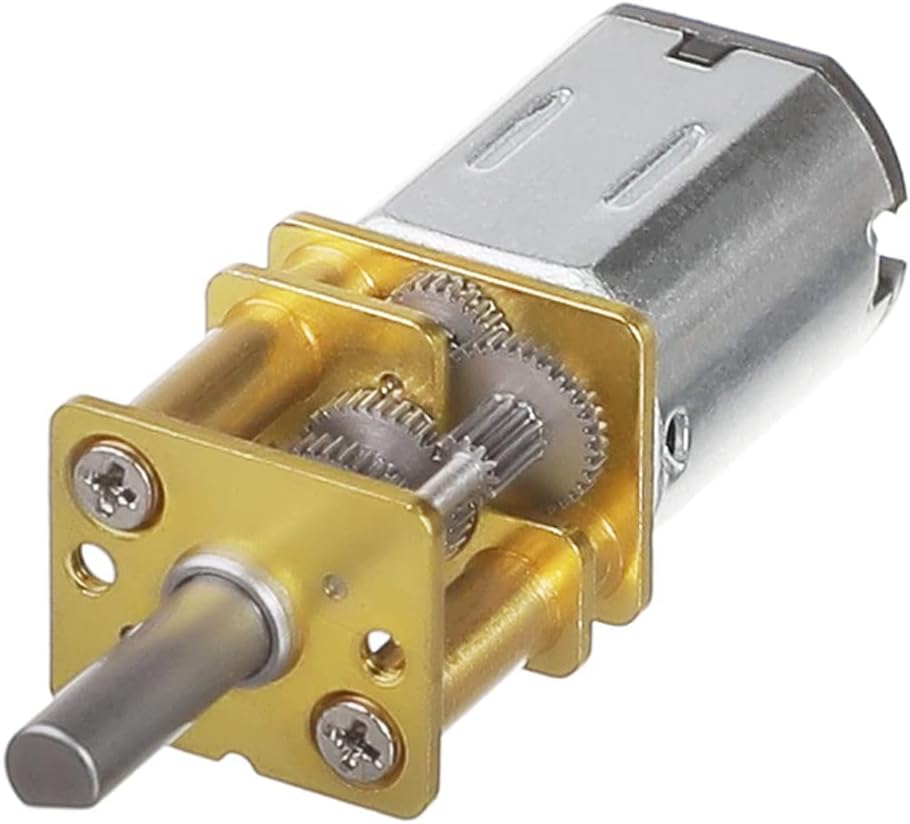

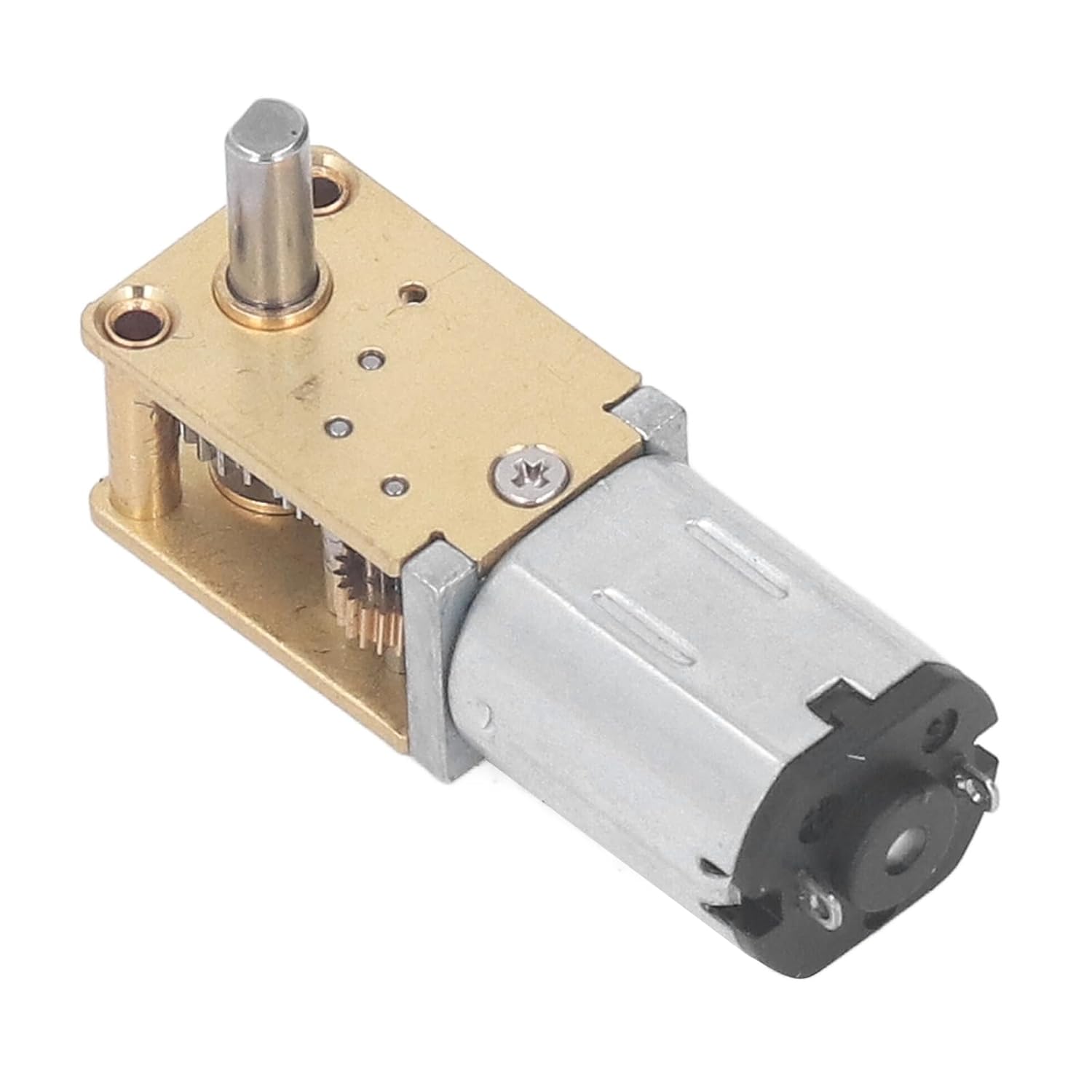

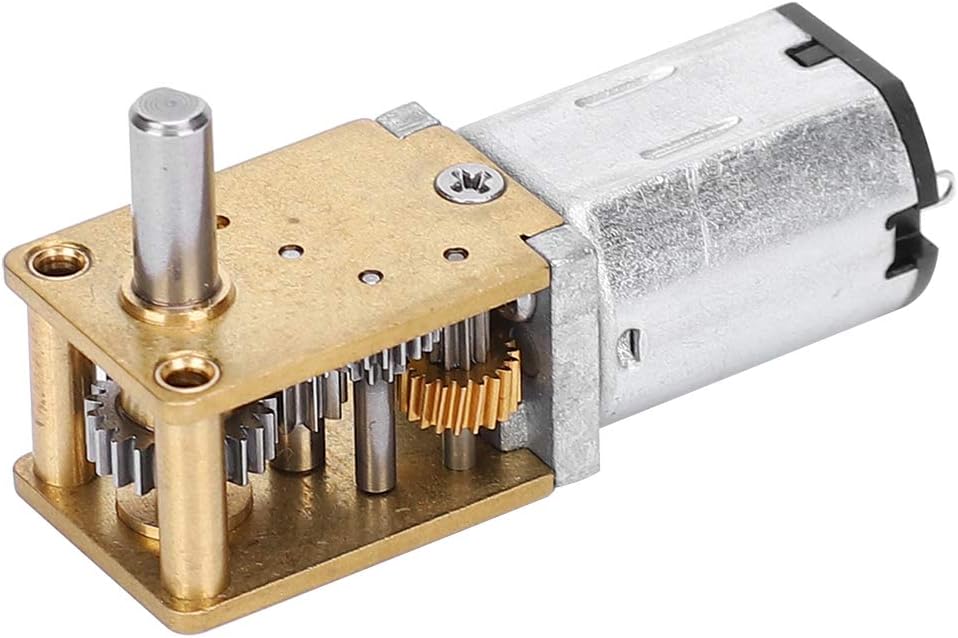

16mm low rpm reduction gear motor for 3D printer equipment and etc.

Product Description

Can be customized

Voltage scope: 1.5 to 6V

Rating voltage: 6V

No-loading:

Speed: 17rpm

Current: 120mA

On-loading:

Speed: 14rpm

Current: 200mA

Torque: 729gf.cm

Output: 0.3W

Gear Box Length: 23.7mm

Output power: 0.01 to 0.5W

Gear ratio: 576:1

We also have the following items:

| Model | Application Parameters | Rated Torque of Gear Box | Instant Torque of Gear Box | Gear Ratio | Gear Box Length L1 |

|||||||

| Rated | At No Load | At Rated Load | Overall Length L |

|||||||||

| Voltage | Speed | Current | Speed | Current | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWPD016016-36 | 6.0 | 286 | 110 | 229 | 200 | 92 | 9.0 | 33.8 | 1000 | 4000 | 36 | 15.1 |

| ZWPD016016-64 | 6.0 | 161 | 120 | 129 | 200 | 108 | 10.6 | 38.1 | 1500 | 5000 | 64 | 19.4 |

| ZWPD016016-96 | 6.0 | 107 | 120 | 86 | 200 | 162 | 15.9 | 1500 | 5000 | 96 | ||

| ZWPD016016-144 | 6.0 | 71 | 120 | 57 | 200 | 243 | 23.8 | 1500 | 5000 | 144 | ||

| ZWPD016016-216 | 6.0 | 48 | 120 | 38 | 200 | 365 | 35.7 | 1000 | 4000 | 216 | ||

| ZWPD016016-256 | 6.0 | 39 | 120 | 31 | 200 | 324 | 31.8 | 42.4 | 1500 | 5000 | 256 | 23.7 |

| ZWPD016016-384 | 6.0 | 26 | 120 | 21 | 200 | 486 | 48 | 1500 | 5000 | 384 | ||

| ZWPD016016-576 | 6.0 | 17 | 120 | 14 | 200 | 729 | 71 | 1500 | 5000 | 576 | ||

| ZWPD016016-864 | 6.0 | 12 | 120 | 9 | 200 | 1094 | 107 | 1500 | 5000 | 864 | ||

| ZWPD016016-1296 | 6.0 | 8 | 120 | 6 | 200 | 1000 | 98 | 1000 | 4000 | 1296 | ||

above specifications just for reference and customizable according to requirements.

Please let us know your requirements and we will provide you with micro transmission solutions.

2D Drawing:

Detailed Photos

Application

| Smart wearable devices | watch,VR,AR,XR and etc. |

| Household application | kitchen appliances, sewing machines, corn popper, vacuum cleaner, garden tool, sanitary ware, window curtain, intelligent closestool, sweeping robot, power seat, standing desk, electric sofa, TV, computer, treadmill, spyhole, cooker hood, electric drawer, electric mosquito net, intelligent cupboard, intelligent wardrobe, automatic soap dispenser, UV baby bottle sterilizer, lifting hot pot cookware, dishwasher, washing machine, food breaking machine, dryer, air conditioning, dustbin, coffee machine, whisk,smart lock,bread maker,Window cleaning robot and etc. |

| communication equipment | 5G base station,video conference,mobile phone and etc. |

| Office automation equipments | scanners, printers, multifunction machines copy machines, fax (FAX paper cutter), computer peripheral, bank machine, screen, lifting socket, display,notebook PC and etc. |

| Automotive products | conditioning damper actuator, car DVD,door lock actuator, retractable rearview mirror, meters, optic axis control device, head light beam level adjuster, car water pump, car antenna, lumbar support, EPB, car tail gate electric putter, HUD, head-up display, vehicle sunroof, EPS, AGS, car window, head restraint, E-booster, car seat, vehicle charging station and etc. |

| Toys and models | radio control model, automatic cruise control, ride-on toy, educational robot, programming robot, medical robot, automatic feeder, intelligent building blocks, escort robot and etc. |

| Medical equipments | blood pressure meter, breath machine, medical cleaning pump, medical bed, blood pressure monitors, medical ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleaning pump for orthopedic surgery,electronic cigarette, eyebrow pencil,fascia gun, , surgical robot,laboratory automation and etc. |

| Industrials | flow control valves, seismic testing,automatic reclosing,Agricultural unmanned aerial vehicle,automatic feeder ,intelligent express cabinet and etc. |

| Electric power tools | electric drill, screwdriver,garden tool and etc. |

| Precision instruments | optics instruments,automatic vending machine, wire-stripping machine and etc. |

| Personal care | tooth brush, hair clipper, electric shaver, massager, vibrator, hair dryer, rubdown machine, scissor hair machine, foot grinder,anti-myopia pen, facial beauty equipment, hair curler,Electric threading knife,POWER PERFECT PORE, Puff machine,eyebrow tweezers and etc. |

| Consumer electronics | camera, mobile phone,digital camera, automatic retracting device,camcorder, kinescope DVD,headphone stereo, cassette tape recorder, bluetooth earbud charging case, turntable, tablet,UAV(unmanned aerial vehicle),surveillance camera,PTZ camera, rotating smart speaker and etc. |

| robots | educational robot, programming robot, medical robot, escort robot and etc. |

Company Profile

HangZhou CHINAMFG Machinery & Electronics Co., Ltd was established in 2001,We provide the total drive solution for customers from design, tooling fabrication, components manufacturing and assembly.

Workshop

Testing Equipment

1) Competitive Advantages

- 1) Competitive Advantages

19+year experience in manufacturing motor gearbox

We provide technical support from r&d, prototype, testing, assembly and serial production , ODM &OEM

Competitive Price

Product Performance: Low noise, High efficiency, Long lifespan

Prompt Delivery: 15 working days after payment

Small Orders Accepted

2) Main Products

-

Precision reduction gearbox and its diameter:3.4mm-38mm,voltage:1.5-24V,power: 0.01-40W,output speed:5-2000rpm and output torque:1.0 gf.cm -50kgf.cm,

- Customized worm and gear transmission machinery;

- Precise electromechanical motion module;

- Precise component and assembly of plastic and metal powder injection.

Our Services

- ODM & OEM

- Gearbox design and development

- Related technology support

- Micro drive gearbox custom solution

Packaging & Shipping

1) Packing Details

packed in nylon firstly, then carton, and then reinforced with wooden case for outer packing.

Or according to client’s requirement.

2) Shipping Details

samples will be shipped within 10 days;

batch order leading time according to the actual situation.

Certifications

Certifications

We Have passed to hold ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and more…

FAQ

FAQ

1. Can you make the gearbox with custom specifications?

YES. We have design and development team, also a great term of engineers, each of them have

many work years experience.

2.Do you provide the samples?

YES. Our company can provide the samples to you, and the delivery time is about 5-15days according to the specification of gearbox you need.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the beginning of our business, we accept small order.

4. Do you have the item in stock?

I am sorry we donot have the item in stock, All products are made with orders.

5. Do you provide technology support?

YES. Our company have design and development team, we can provide technology support if you

need.

6.How to ship to us?

We will ship the goods to you according to the DHL or UPS or FEDEX etc account you provide.

7.How to pay the money?

We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

8. How can I know the product is suitable for me?

Frist, you need to provide us the more details information about the product. We will recommend the item to you according to your requirement of specification. After you confirm, we will prepare the samples to you. also we will offer some good advances according to your product use.

9. Can I come to your company to visit?

YES, you can come to our company to visit at anytime, and welcome to visit our company.

10. How do contact us ?

Please send an inquiry

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools, 3D Printer |

|---|---|

| Operating Speed: | Low Speed |

| Excitation Mode: | Permanent Magnet |

| Function: | Control |

| Casing Protection: | Drip-Proof |

| Number of Poles: | Customize |

| Customization: |

Available

|

|

|---|

Are gear motors suitable for both heavy-duty industrial applications and smaller-scale uses?

Yes, gear motors are suitable for both heavy-duty industrial applications and smaller-scale uses. Their versatility and ability to provide torque multiplication make them valuable in a wide range of applications. Here’s a detailed explanation of why gear motors are suitable for both types of applications:

1. Heavy-Duty Industrial Applications:

Gear motors are commonly used in heavy-duty industrial applications due to their robustness and ability to handle high loads. Here are the reasons why they are suitable for such applications:

- Torque Multiplication: Gear motors are designed to provide high torque output, making them ideal for applications that require substantial force to move or operate heavy machinery, conveyors, or equipment.

- Load Handling: Industrial settings often involve heavy loads and demanding operating conditions. Gear motors, with their ability to handle high loads, are well-suited for tasks such as lifting, pulling, pushing, or driving heavy materials or equipment.

- Durability: Heavy-duty industrial applications require components that can withstand harsh environments, frequent use, and demanding operating conditions. Gear motors are typically constructed with durable materials and designed to withstand heavy vibrations, shock loads, and temperature variations.

- Speed Reduction: Many industrial processes require the reduction of motor speed to achieve the desired output speed. Gear motors offer precise speed reduction capabilities through gear ratios, allowing for optimal control and operation of machinery and equipment.

2. Smaller-Scale Uses:

While gear motors excel in heavy-duty industrial applications, they are also suitable for smaller-scale uses across various industries and applications. Here’s why gear motors are well-suited for smaller-scale uses:

- Compact Size: Gear motors are available in compact sizes, making them suitable for applications with limited space or small-scale machinery, devices, or appliances.

- Torque and Power Control: Even in smaller-scale applications, there may be a need for torque multiplication or precise power control. Gear motors can provide the necessary torque and power output for tasks such as precise positioning, controlling speed, or driving small loads.

- Versatility: Gear motors come in various configurations, such as parallel shaft, planetary, or worm gear designs, offering flexibility to match specific requirements. They can be adapted to different applications, including robotics, medical devices, automotive systems, home automation, and more.

- Efficiency: Gear motors are designed to be efficient, converting the electrical input power into mechanical output power with minimal losses. This efficiency is advantageous for smaller-scale applications where energy conservation and battery life are critical.

Overall, gear motors are highly versatile and suitable for both heavy-duty industrial applications and smaller-scale uses. Their ability to provide torque multiplication, handle high loads, offer precise speed control, and accommodate various sizes and configurations makes them a reliable choice in a wide range of applications. Whether it’s powering large industrial machinery or driving small-scale automation systems, gear motors provide the necessary torque, control, and durability required for efficient operation.

How does the voltage and power rating of a gear motor impact its suitability for different tasks?

The voltage and power rating of a gear motor are important factors that influence its suitability for different tasks. These specifications determine the motor’s electrical characteristics and its ability to perform specific tasks effectively. Here’s a detailed explanation of how voltage and power rating impact the suitability of a gear motor for different tasks:

1. Voltage Rating:

The voltage rating of a gear motor refers to the electrical voltage it requires to operate optimally. Here’s how the voltage rating affects suitability:

- Compatibility with Power Supply: The gear motor’s voltage rating must match the available power supply. Using a motor with a voltage rating that is too high or too low for the power supply can lead to improper operation or damage to the motor.

- Electrical Safety: Adhering to the specified voltage rating ensures electrical safety. Using a motor with a higher voltage rating than recommended can pose safety hazards, while using a motor with a lower voltage rating may result in inadequate performance.

- Application Flexibility: Different tasks or applications may have specific voltage requirements. For example, low-voltage gear motors are commonly used in battery-powered devices or applications with low-power requirements, while high-voltage gear motors are suitable for industrial applications or tasks that require higher power output.

2. Power Rating:

The power rating of a gear motor indicates its ability to deliver mechanical power. It is typically specified in units of watts (W) or horsepower (HP). The power rating impacts the suitability of a gear motor in the following ways:

- Load Capacity: The power rating determines the maximum load that a gear motor can handle. Motors with higher power ratings are capable of driving heavier loads or handling tasks that require more torque.

- Speed and Torque: The power rating affects the motor’s speed and torque characteristics. Motors with higher power ratings generally offer higher speeds and greater torque output, making them suitable for applications that require faster operation or the ability to overcome higher resistance or loads.

- Efficiency and Energy Consumption: The power rating is related to the motor’s efficiency and energy consumption. Higher power-rated motors may be more efficient, resulting in lower energy losses and reduced operating costs over time.

- Thermal Considerations: Motors with higher power ratings may generate more heat during operation. It is crucial to consider the motor’s power rating in relation to its thermal management capabilities to prevent overheating and ensure long-term reliability.

Considerations for Task Suitability:

When selecting a gear motor for a specific task, it is important to consider the following factors in relation to the voltage and power rating:

- Required Torque and Load: Assess the torque and load requirements of the task to ensure that the gear motor’s power rating is sufficient to handle the expected load without being overloaded.

- Speed and Precision: Consider the desired speed and precision of the task. Motors with higher power ratings generally offer better speed control and accuracy.

- Power Supply Availability: Evaluate the availability and compatibility of the power supply with the gear motor’s voltage rating. Ensure that the power supply can provide the required voltage for the motor’s optimal operation.

- Environmental Factors: Consider any specific environmental factors, such as temperature or humidity, that may impact the gear motor’s performance. Ensure that the motor’s voltage and power ratings are suitable for the intended operating conditions.

In summary, the voltage and power rating of a gear motor have significant implications for its suitability in different tasks. The voltage rating determines compatibility with the power supply and ensures electrical safety, while the power rating influences load capacity, speed, torque, efficiency, and thermal considerations. When choosing a gear motor, it is crucial to carefully evaluate the task requirements and consider the voltage and power rating in relation to factors such as torque, speed, power supply availability, and environmental conditions.

What are the different types of gears used in gear motors, and how do they impact performance?

Various types of gears are used in gear motors, each with its unique characteristics and impact on performance. The choice of gear type depends on the specific requirements of the application, including torque, speed, efficiency, noise level, and space constraints. Here’s a detailed explanation of the different types of gears used in gear motors and their impact on performance:

1. Spur Gears:

Spur gears are the most common type of gears used in gear motors. They have straight teeth that are parallel to the gear’s axis and mesh with another spur gear to transmit power. Spur gears provide high efficiency, reliable operation, and cost-effectiveness. However, they can generate significant noise due to the meshing of teeth, and they may produce axial thrust forces. Spur gears are suitable for applications that require high torque transmission and moderate to high rotational speeds.

2. Helical Gears:

Helical gears have angled teeth that are cut at an angle to the gear’s axis. This helical tooth configuration enables gradual engagement and smoother tooth contact, resulting in reduced noise and vibration compared to spur gears. Helical gears provide higher load-carrying capacity and are suitable for applications that require high torque transmission and moderate to high rotational speeds. They are commonly used in gear motors where low noise operation is desired, such as in automotive applications and industrial machinery.

3. Bevel Gears:

Bevel gears have teeth that are cut on a conical surface. They are used to transmit power between intersecting shafts, usually at right angles. Bevel gears can have straight teeth (straight bevel gears) or curved teeth (spiral bevel gears). These gears provide efficient power transmission and precise motion control in applications where shafts need to change direction. Bevel gears are commonly used in gear motors for applications such as steering systems, machine tools, and printing presses.

4. Worm Gears:

Worm gears consist of a worm (a type of screw) and a mating gear called a worm wheel or worm gear. The worm has a helical thread that meshes with the worm wheel, resulting in a compact and high gear reduction ratio. Worm gears provide high torque transmission, low noise operation, and self-locking properties, which prevent reverse motion. They are commonly used in gear motors for applications that require high gear reduction and locking capabilities, such as in lifting mechanisms, conveyor systems, and machine tools.

5. Planetary Gears:

Planetary gears, also known as epicyclic gears, consist of a central sun gear, multiple planet gears, and an outer ring gear. The planet gears mesh with both the sun gear and the ring gear, creating a compact and efficient gear system. Planetary gears offer high torque transmission, high gear reduction ratios, and excellent load distribution. They are commonly used in gear motors for applications that require high torque and compact size, such as in robotics, automotive transmissions, and industrial machinery.

6. Rack and Pinion:

Rack and pinion gears consist of a linear rack (a straight toothed bar) and a pinion gear (a spur gear with a small diameter). The pinion gear meshes with the rack to convert rotary motion into linear motion or vice versa. Rack and pinion gears provide precise linear motion control and are commonly used in gear motors for applications such as linear actuators, CNC machines, and steering systems.

The choice of gear type in a gear motor depends on factors such as the desired torque, speed, efficiency, noise level, and space constraints. Each type of gear offers specific advantages and impacts the performance of the gear motor differently. By selecting the appropriate gear type, gear motors can be optimized for their intended applications, ensuring efficient and reliable power transmission.

editor by CX 2024-05-17

China factory ZD Long Life Low Noise UL, CE, ISO9001, CCC, RoHS Approved AC Gear Reduction Motor manufacturer

Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

Detailed Photos

Product Parameters

Other Related Products

Click here to find what you are looking for:

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Single-Phase |

| Function: | Driving |

| Casing Protection: | Closed Type |

| Number of Poles: | 2 |

| Customization: |

Available

|

|

|---|

What types of feedback mechanisms are commonly integrated into gear motors for control?

Gear motors often incorporate feedback mechanisms to provide control and improve their performance. These feedback mechanisms enable the motor to monitor and adjust its operation based on various parameters. Here are some commonly integrated feedback mechanisms in gear motors:

1. Encoder Feedback:

An encoder is a device that provides position and speed feedback by converting the motor’s mechanical motion into electrical signals. Encoders commonly used in gear motors include:

- Incremental Encoders: These encoders provide information about the motor’s shaft position and speed relative to a reference point. They generate pulses as the motor rotates, allowing precise measurement of position and speed changes.

- Absolute Encoders: Absolute encoders provide the precise position of the motor’s shaft within a full revolution. They do not require a reference point and provide accurate feedback even after power loss or motor restart.

2. Hall Effect Sensors:

Hall effect sensors use the principle of the Hall effect to detect the presence and strength of a magnetic field. They are commonly used in gear motors for speed and position sensing. Hall effect sensors provide feedback by detecting changes in the motor’s magnetic field and converting them into electrical signals.

3. Current Sensors:

Current sensors monitor the electrical current flowing through the motor’s windings. By measuring the current, these sensors provide feedback regarding the motor’s torque, load conditions, and power consumption. Current sensors are essential for motor control strategies such as current limiting, overcurrent protection, and closed-loop control.

4. Temperature Sensors:

Temperature sensors are integrated into gear motors to monitor the motor’s temperature. They provide feedback on the motor’s thermal conditions, allowing the control system to adjust the motor’s operation to prevent overheating. Temperature sensors are crucial for ensuring the motor’s reliability and preventing damage due to excessive heat.

5. Hall Effect Limit Switches:

Hall effect limit switches are used to detect the presence or absence of a magnetic field within a specific range. They are commonly employed as end-of-travel or limit switches in gear motors. Hall effect limit switches provide feedback to the control system, indicating when the motor has reached a specific position or when it has moved beyond the allowed range.

6. Resolver Feedback:

A resolver is an electromagnetic device used to determine the position and speed of a rotating shaft. It provides feedback by generating sine and cosine signals that correspond to the shaft’s angular position. Resolver feedback is commonly used in high-performance gear motors requiring accurate position and speed control.

These feedback mechanisms, when integrated into gear motors, enable precise control, monitoring, and adjustment of various motor parameters. By utilizing feedback signals from encoders, Hall effect sensors, current sensors, temperature sensors, limit switches, or resolvers, the control system can optimize the motor’s performance, ensure accurate positioning, maintain speed control, and protect the motor from excessive loads or overheating.

How do gear motors compare to other types of motors in terms of power and efficiency?

Gear motors can be compared to other types of motors in terms of power output and efficiency. The choice of motor type depends on the specific application requirements, including the desired power level, efficiency, speed range, torque characteristics, and control capabilities. Here’s a detailed explanation of how gear motors compare to other types of motors in terms of power and efficiency:

1. Gear Motors:

Gear motors combine a motor with a gear mechanism to deliver increased torque output and improved control. The gear reduction enables gear motors to provide higher torque while reducing the output speed. This makes gear motors suitable for applications that require high torque, precise positioning, and controlled movements. However, the gear reduction process introduces mechanical losses, which can slightly reduce the overall efficiency of the system compared to direct-drive motors. The efficiency of gear motors can vary depending on factors such as gear quality, lubrication, and maintenance.

2. Direct-Drive Motors:

Direct-drive motors, also known as gearless or integrated motors, do not use a gear mechanism. They provide a direct connection between the motor and the load, eliminating the need for gear reduction. Direct-drive motors offer advantages such as high efficiency, low maintenance, and compact design. Since there are no gears involved, direct-drive motors experience fewer mechanical losses and can achieve higher overall efficiency compared to gear motors. However, direct-drive motors may have limitations in terms of torque output and speed range, and they may require more complex control systems to achieve precise positioning.

3. Stepper Motors:

Stepper motors are a type of gear motor that excels in precise positioning applications. They operate by converting electrical pulses into incremental steps of movement. Stepper motors offer excellent positional accuracy and control. They are capable of precise positioning and can hold a position without power. Stepper motors have relatively high torque at low speeds, making them suitable for applications that require precise control and positioning, such as robotics, 3D printers, and CNC machines. However, stepper motors may have lower overall efficiency compared to direct-drive motors due to the additional power required to overcome the detents between steps.

4. Servo Motors:

Servo motors are another type of gear motor known for their high torque, high speed, and excellent positional accuracy. Servo motors combine a motor, a feedback device (such as an encoder), and a closed-loop control system. They offer precise control over position, speed, and torque. Servo motors are widely used in applications that require accurate and responsive positioning, such as industrial automation, robotics, and camera pan-tilt systems. Servo motors can achieve high efficiency when properly optimized and controlled but may have slightly lower efficiency compared to direct-drive motors due to the additional complexity of the control system.

5. Efficiency Considerations:

When comparing power and efficiency among different motor types, it’s important to consider the specific requirements and operating conditions of the application. Factors such as load characteristics, speed range, duty cycle, and control requirements influence the overall efficiency of the motor system. While direct-drive motors generally offer higher efficiency due to the absence of mechanical losses from gears, gear motors can deliver higher torque output and enhanced control capabilities. The efficiency of gear motors can be optimized through proper gear selection, lubrication, and maintenance practices.

In summary, gear motors offer increased torque and improved control compared to direct-drive motors. However, gear reduction introduces mechanical losses that can slightly impact the overall efficiency of the system. Direct-drive motors, on the other hand, provide high efficiency and compact design but may have limitations in terms of torque and speed range. Stepper motors and servo motors, both types of gear motors, excel in precise positioning applications but may have slightly lower efficiency compared to direct-drive motors. The selection of the most suitable motor type depends on the specific requirements of the application, balancing power, efficiency, speed range, and control capabilities.

Can you explain the advantages of using gear motors in various mechanical systems?

Gear motors offer several advantages when utilized in various mechanical systems. Their unique characteristics make them well-suited for applications that require controlled power transmission, precise speed control, and torque amplification. Here’s a detailed explanation of the advantages of using gear motors:

1. Torque Amplification:

One of the key advantages of gear motors is their ability to amplify torque. By using different gear ratios, gear motors can increase or decrease the output torque from the motor. This torque amplification is crucial in applications that require high torque output, such as lifting heavy loads or operating machinery with high resistance. Gear motors allow for efficient power transmission, enabling the system to handle demanding tasks effectively.

2. Speed Control:

Gear motors provide precise speed control, allowing for accurate and controlled movement in mechanical systems. By selecting the appropriate gear ratio, the rotational speed of the output shaft can be adjusted to match the requirements of the application. This speed control capability ensures that the mechanical system operates at the desired speed, whether it needs to be fast or slow. Gear motors are commonly used in applications such as conveyors, robotics, and automated machinery, where precise speed control is essential.

3. Directional Control:

Another advantage of gear motors is their ability to control the rotational direction of the output shaft. By using different types of gears, such as spur gears, bevel gears, or worm gears, the direction of rotation can be easily changed. This directional control is beneficial in applications that require bidirectional movement, such as in actuators, robotic arms, and conveyors. Gear motors offer reliable and efficient directional control, contributing to the versatility and functionality of mechanical systems.

4. Efficiency and Power Transmission:

Gear motors are known for their high efficiency in power transmission. The gear system helps distribute the load across multiple gears, reducing the strain on individual components and minimizing power losses. This efficient power transmission ensures that the mechanical system operates with optimal energy utilization and minimizes wasted power. Gear motors are designed to provide reliable and consistent power transmission, resulting in improved overall system efficiency.

5. Compact and Space-Saving Design:

Gear motors are compact in size and offer a space-saving solution for mechanical systems. By integrating the motor and gear system into a single unit, gear motors eliminate the need for additional components and reduce the overall footprint of the system. This compact design is especially beneficial in applications with limited space constraints, allowing for more efficient use of available space while still delivering the necessary power and functionality.

6. Durability and Reliability:

Gear motors are designed to be robust and durable, capable of withstanding demanding operating conditions. The gear system helps distribute the load, reducing the stress on individual gears and increasing overall durability. Additionally, gear motors are often constructed with high-quality materials and undergo rigorous testing to ensure reliability and longevity. This makes gear motors well-suited for continuous operation in industrial and commercial applications, where reliability is crucial.

By leveraging the advantages of torque amplification, speed control, directional control, efficiency, compact design, durability, and reliability, gear motors provide a reliable and efficient solution for various mechanical systems. They are widely used in industries such as robotics, automation, manufacturing, automotive, and many others, where precise and controlled mechanical power transmission is essential.

editor by CX 2024-05-17

China high quality 12V 24V 48V Variable Speed High Power Electric Car Brushless DC Planetary Gear Servo Motor for Micro Electric Pump Fan Chain Grinder vacuum pump and compressor

Product Description

Product Description

| model | Number of poles | Phase | Rated voltage | Rated speed | Continuous locked-rotor torque | Rated torque | Rated power | Peak torque |

| Units | VDC | RPM | N.m | N.m | W | N.m | ||

| 42BYA075B030C-02 | 4 | 3 | 24 | 3000 | 0.192 | 0.16 | 50 | 0.48 |

| model | Peak current | Torque constant | Back EMF | Motor length | Motor length | voltage range | Range of rotation | weight |

| Units | A | Nm/A | V/KRPM | g.cMoment of inertia | mm | VDC | RPM | Kg |

| 42BYA075B030C-02 | 9.6 | 0.05 | 3.947 | 14.6 | 134 | 24~48 | 1000~3000 | 1.0 |

Product Parameters

Quiet stable and reliable for long life operation

1.Voltage: 24 VDC

2.Number of phases: 3

3.Number of levels: 4

4.Line-to-line resistance: 1.45±10%ohms

5.Line-to-line inductance: 1.27±20%mH

6.Rated current: 3.2A

7.Rated power: 50W

8.No-load speed: 4300 rpm

9.Insulation class: B

10.Reduction ratio: 1:58.22

11.Output torque: 7.5 N.m

12.Output speed: 51.5 rpm

13.We can design the special voltage and shaft and so on

Jintian Imp. & Exp Co. Ltd opened in 2008 to facilitate international trade between China and the rest of the world. The young firm grew quickly, gaining a reputation for integrity, efficiency and astute knowledge of local market.

Throughout its 10 more years history, CHINAMFG has sought to connect customers with opportunities. While that purpose has remained unchanged, CHINAMFG has succeeded by positioning itself where the growth is and by aligning itself to the major economic trends of the time.

After being funded in ZheJiang , China to facilitate local and international trade, CHINAMFG expanded rapidly to capture the increasing flow of commerce between Asia, Europe and North America. Since then, CHINAMFG has continued to grow in line with changing trade patterns and developing markets, pioneering modern international trade practices in many countries. Built over 10 years, this global network is highly distinctive, difficult to replicate and ideally positioned for the world’s top trade corridors.

Our ability to connect customers remains absolutely central to the company’s strategy today, which aims to establish CHINAMFG as the world”s leading international trade company. Above all, we remain dedicated to the purpose that CHINAMFG was founded to serve: Connecting customers to opportunities, enabling businesses to CHINAMFG and economies to prosper, and helping people to fulfill their hopes and dreams.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Three-Phase |

| Samples: |

US$ 162/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What role do materials play in the design and manufacturing of reliable micro gear motors?

Materials play a critical role in the design and manufacturing of reliable micro gear motors. Here’s how they contribute:

- Gear Material: The choice of material for the gears is crucial for the overall performance and reliability of micro gear motors. Gears are subjected to high loads, friction, and wear during operation. Common materials used for gears include steel, stainless steel, brass, and various engineering plastics. The selected material should have high strength, good wear resistance, and low friction characteristics to ensure smooth and efficient power transmission, minimize gear failure, and prolong the motor’s lifespan.

- Motor Housing: The material used for the motor housing affects its durability, thermal management, and protection against environmental factors. Common materials for motor housings include aluminum, stainless steel, and engineering plastics. The housing should provide structural integrity, efficient heat dissipation, and protection against dust, moisture, and other contaminants to maintain the motor’s reliability and performance in various operating conditions.

- Bearing Materials: Bearings are essential components in micro gear motors as they reduce friction and enable smooth rotation of the motor shaft. The choice of bearing material is crucial for ensuring reliable and long-lasting operation. Common bearing materials include stainless steel, ceramics, and various self-lubricating materials. The selected material should have low friction, high load-bearing capacity, and resistance to wear and corrosion to minimize power losses, maintain efficiency, and extend the motor’s lifespan.

- Magnetic Materials: In motors that utilize permanent magnets, such as brushless DC (BLDC) motors, the choice of magnetic material is crucial for generating and maintaining magnetic fields. Neodymium magnets are commonly used due to their high magnetic strength and energy efficiency. The quality and characteristics of the magnetic material directly impact the motor’s performance, torque output, and overall efficiency.

- Electrical Insulation: Micro gear motors often involve the flow of electrical current through the motor windings. Insulation materials, such as enamel or varnish, are used to electrically isolate the windings and prevent short circuits. The selected insulation material should have high dielectric strength, good thermal stability, and resistance to environmental factors to ensure reliable electrical insulation and prevent motor failures.

By carefully selecting appropriate materials for gears, motor housing, bearings, magnetic components, and electrical insulation, designers and manufacturers can optimize the reliability, efficiency, and performance of micro gear motors. The materials should be chosen based on the specific requirements of the application, considering factors such as load capacity, operating conditions, environmental factors, and cost-effectiveness.

Can you provide examples of innovative uses of micro gear motors in modern technology?

Micro gear motors have found innovative applications across various modern technologies. Here are some examples:

- Drones: Micro gear motors are commonly used in drones to drive the propellers and control the flight. Their compact size, lightweight design, and precise control capabilities make them ideal for achieving stable and agile flight maneuvers.

- Robotics: Micro gear motors play a crucial role in robotics, powering the joints and actuators of robotic arms, grippers, and humanoid robots. Their precise control, compact form factor, and high torque-to-size ratio enable robots to perform delicate and precise manipulations in industrial automation, medical procedures, and research applications.

- Automotive Systems: Micro gear motors are used in various automotive systems, such as power windows, door locks, and seat adjustments. Their small size and high torque allow for efficient and reliable operation of these mechanisms within the limited space available in vehicles.

- Medical Devices: Micro gear motors are utilized in medical devices and equipment, including surgical robots, prosthetics, insulin pumps, and lab automation systems. Their precise control, compact size, and low power consumption make them suitable for applications requiring fine movements, accurate dosing, and miniaturization.

- Consumer Electronics: Micro gear motors are incorporated into numerous consumer electronic devices. They can be found in cameras for lens movement and autofocus, wearable devices for haptic feedback and vibration, and home appliances for precise control of valves, fans, and robotic components.

- Smart Home Systems: Micro gear motors are employed in smart home systems to control various functions, such as motorized curtains, blinds, and awnings. Their precise control, quiet operation, and compatibility with automation systems allow for convenient and customizable control of these home features.

These examples represent just a few of the many innovative uses of micro gear motors in modern technology. Their versatility, precision, and compact design make them valuable components in a wide range of applications, contributing to advancements in automation, robotics, electronics, and beyond.

In which applications are micro gear motors commonly used due to their compact size?

Micro gear motors find applications in various industries where their compact size is advantageous. Here are some common applications where micro gear motors are commonly used:

1. Micro Robotics:

Micro gear motors are extensively used in micro robotics applications. These motors provide the necessary torque and precision for controlling the movements of miniature robot platforms, robotic arms, grippers, and other robotic components. Their small size allows for intricate and precise motion control in confined spaces.

2. Medical Devices:

In the medical field, micro gear motors are employed in various devices and equipment, including medical robots, surgical instruments, diagnostic devices, and drug delivery systems. Their compact size enables integration into portable and handheld medical devices while ensuring precise and controlled movements for accurate diagnostics and minimally invasive procedures.

3. Automotive Systems:

Micro gear motors are used in automotive systems that require compact and lightweight actuators. They find applications in power windows, door locks, seat adjustment mechanisms, mirror adjustment, and HVAC controls. The small size of micro gear motors allows for efficient utilization of space within the vehicle while providing reliable and precise operation.

4. Consumer Electronics:

Micro gear motors are found in various consumer electronic devices. They are used in camera autofocus mechanisms, zoom controls, robotic toys, smart home devices, and wearable technology. The compact size of micro gear motors enables seamless integration into these devices, providing precise and controlled motion capabilities.

5. Industrial Automation:

In industrial automation applications, micro gear motors are utilized in small-scale machinery, robotics, and automated systems. They are used in conveyor systems, pick-and-place machines, miniature actuators, and precision positioning systems. The small size and high gearing ratio of micro gear motors allow for accurate and repeatable positioning in tight spaces.

6. Aerospace and Defense:

Micro gear motors are employed in aerospace and defense applications, including drones, unmanned aerial vehicles (UAVs), miniature satellites, and guidance systems. Their compact size and lightweight properties are crucial for reducing the overall weight and improving maneuverability in these applications.

7. Scientific and Laboratory Equipment:

Micro gear motors are used in scientific instruments, laboratory equipment, and research devices. They find applications in precision syringe pumps, sample handling systems, microfluidic devices, and motion control mechanisms for optical instruments. The compact size and precise motion control capabilities of micro gear motors support accurate and controlled experimentation and analysis.

8. Industrial and Manufacturing:

In industrial and manufacturing settings, micro gear motors are utilized in small-scale machinery, conveyors, packaging equipment, and assembly systems. They provide compact and efficient motion control for precise material handling, part positioning, and automation processes.

These are just a few examples of the many applications where micro gear motors are commonly used due to their compact size. Their small form factor and precise motion control capabilities make them ideal for applications where space constraints, weight reduction, and accurate motion control are crucial factors.

editor by CX 2024-05-17

China factory ZD Single or Three Phase Helical Gear Small AC Motor For Packing Machine vacuum pump design

Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

Product Parameters

| <1000m | ||

| Starting | Direct start | 0.1-.02kw capacitor 0.4-1.5kw double capacitors |

| Standard | GB755/IEC-60034 | |

Main parts notes:

| Parts name | Notes |

| Gearbox | The output shaft diameter of gearbox 1#,2#,3# are 18,22,28mm separately.the material of gearbox is alum alloy.4#,5#,6# are 32,40,50 respectively.Gearbox is made of cast iron. |

| Gear piece | The material 40Cr mixes to HB280,then dealed with high frequency quencher HRC50.Gear should be processed by milling with high precision.The class is 6. |

| Gear shaft | The material 20CrMnTi will be changed into HRC60 through processing of cementite quencher.Gear shaft will be processed with gear hobbing.Precision class is 6. |

| Motor shaft | The material 40Cr mixes to HB280,then dealed with high frequency quencher HRC54.Finally,gear is cut for the second.motor shaft will be processed with gear hobbing.Precision class is 5-6. |

| Ball bearing | We adopt tight bearing with high precision,to make sure longterm running lift. |

| Oil seal | Gear shaft gives priorith to enduring high temp,avoiding oil infiltration. |

| Terminal box | Two type.one is al alloy,which equips good capability of waterproof and dustproof.Protection grade is IP54.The other is steel case with deft structure.Protection grade is IP20. |

Gear of small series:

1.The material of rotor is 40Cr,quench to HRC50-55 after rough rolling,two times hard cutting,the gear precision can arrive ISO class6-7.

2.The material of shafe gear is 20CrMnTi,quench to HRC58-61 after rough rolling,two times hard cutting,the gear precision can arrive ISO class6-7.

2.The material of plate gear is 40Cr,quench to HRC48-51 after rough rolling,grind,the precision can arrive ISO class6-7.

Brake series:

1.Economical and compact.

2.High pressure-resistance,good insulation,insulation class F,can work in different kinds of ambient.

3.Long life,adopting abrasion-resistance lead-free,non asbestos friction plate,making sure the long life.

4.It”s selective of assembling hole diameter and easy assembling.

5.Multiple assembling way meets different customers.

Detailed Photos

Other Related Products

Click here to find what you are looking for:

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Constant Speed |

| Number of Stator: | Single-Phase |

| Function: | Control |

| Casing Protection: | Closed Type |

| Number of Poles: | 4 |

| Customization: |

Available

|

|

|---|

What are the maintenance requirements for gear motors, and how can longevity be maximized?

Gear motors, like any mechanical system, require regular maintenance to ensure optimal performance and longevity. Proper maintenance practices help prevent failures, minimize downtime, and extend the lifespan of gear motors. Here are some maintenance requirements for gear motors and ways to maximize their longevity:

1. Lubrication:

Regular lubrication is essential for gear motors to reduce friction, wear, and heat generation. The gears, bearings, and other moving parts should be properly lubricated according to the manufacturer’s recommendations. Lubricants should be selected based on the motor’s specifications and operating conditions. Regular inspection and replenishment of lubricants, as well as periodic oil or grease changes, should be performed to maintain optimal lubrication levels and ensure long-lasting performance.

2. Inspection and Cleaning:

Regular inspection and cleaning of gear motors are crucial for identifying any signs of wear, damage, or contamination. Inspecting the gears, bearings, shafts, and connections can help detect any abnormalities or misalignments. Cleaning the motor’s exterior and ventilation channels to remove dust, debris, or moisture buildup is also important in preventing malfunctions and maintaining proper cooling. Any loose or damaged components should be repaired or replaced promptly.

3. Temperature and Environmental Considerations:

Monitoring and controlling the temperature and environmental conditions surrounding gear motors can significantly impact their longevity. Excessive heat can degrade lubricants, damage insulation, and lead to premature component failure. Ensuring proper ventilation, heat dissipation, and avoiding overloading the motor can help manage temperature effectively. Similarly, protecting gear motors from moisture, dust, chemicals, and other environmental contaminants is vital to prevent corrosion and damage.

4. Load Monitoring and Optimization:

Monitoring and optimizing the load placed on gear motors can contribute to their longevity. Operating gear motors within their specified load and speed ranges helps prevent excessive stress, overheating, and premature wear. Avoiding sudden and frequent acceleration or deceleration, as well as preventing overloading or continuous operation near the motor’s maximum capacity, can extend its lifespan.

5. Alignment and Vibration Analysis:

Proper alignment of gear motor components, such as gears, couplings, and shafts, is crucial for smooth and efficient operation. Misalignment can lead to increased friction, noise, and premature wear. Regularly checking and adjusting alignment, as well as performing vibration analysis, can help identify any misalignment or excessive vibration that may indicate underlying issues. Addressing alignment and vibration problems promptly can prevent further damage and maximize the motor’s longevity.

6. Preventive Maintenance and Regular Inspections:

Implementing a preventive maintenance program is essential for gear motors. This includes establishing a schedule for routine inspections, lubrication, and cleaning, as well as conducting periodic performance tests and measurements. Following the manufacturer’s guidelines and recommendations for maintenance tasks, such as belt tension checks, bearing replacements, or gear inspections, can help identify and address potential issues before they escalate into major failures.

By adhering to these maintenance requirements and best practices, the longevity of gear motors can be maximized. Regular maintenance, proper lubrication, load optimization, temperature control, and timely repairs or replacements of worn components contribute to the reliable operation and extended lifespan of gear motors.

Can you explain the role of backlash in gear motors and how it’s managed in design?

Backlash plays a significant role in gear motors and is an important consideration in their design and operation. Backlash refers to the slight clearance or play between the teeth of gears in a gear system. It affects the precision, accuracy, and responsiveness of the gear motor. Here’s an explanation of the role of backlash in gear motors and how it is managed in design:

1. Role of Backlash:

Backlash in gear motors can have both positive and negative effects:

- Compensation for Misalignment: Backlash can help compensate for minor misalignments between gears, shafts, or the load. It allows a small amount of movement before engaging the next set of teeth, reducing the risk of damage due to misalignment. This can be particularly beneficial in applications where precise alignment is challenging or subject to variations.

- Negative Impact on Accuracy and Responsiveness: Backlash can introduce a delay or “dead zone” in the motion transmission. When changing the direction of rotation or reversing the load, the gear teeth must first overcome the clearance or play before engaging in the opposite direction. This delay can reduce the overall accuracy, responsiveness, and repeatability of the gear motor, especially in applications that require precise positioning or rapid changes in direction or speed.

2. Managing Backlash in Design:

Designers employ various techniques to manage and minimize backlash in gear motors:

- Tight Manufacturing Tolerances: Proper manufacturing techniques and tight tolerances can help minimize backlash. Precision machining and quality control during the production of gears and gear components ensure closer tolerances, reducing the amount of play between gear teeth.

- Preload or Pre-tensioning: Applying a preload or pre-tensioning force to the gear system can help reduce backlash. This technique involves introducing an initial force or tension that eliminates the clearance between gear teeth. It ensures immediate contact and engagement of the gear teeth, minimizing the dead zone and improving the overall responsiveness and accuracy of the gear motor.

- Anti-Backlash Gears: Anti-backlash gears are designed specifically to minimize or eliminate backlash. They typically feature modifications to the gear tooth profile, such as modified tooth shapes or special tooth arrangements, to reduce clearance. Anti-backlash gears can be used in gear motor designs to improve precision and minimize the effects of backlash.

- Backlash Compensation: In some cases, backlash compensation techniques can be employed. These techniques involve monitoring the position or movement of the load and applying control algorithms to compensate for the backlash. By accounting for the clearance and adjusting the control signals accordingly, the effects of backlash can be mitigated, improving accuracy and responsiveness.

3. Application-Specific Considerations:

The management of backlash in gear motors should be tailored to the specific application requirements:

- Positioning Accuracy: Applications that require precise positioning, such as robotics or CNC machines, may require tighter backlash control to ensure accurate and repeatable movements.

- Dynamic Response: Applications that involve rapid changes in direction or speed, such as high-speed automation or servo control systems, may require reduced backlash to maintain responsiveness and minimize overshoot or lag.

- Load Characteristics: The nature of the load and its impact on the gear system should be considered. Heavy loads or applications with significant inertial forces may require additional backlash management techniques to maintain stability and accuracy.

In summary, backlash in gear motors can affect precision, accuracy, and responsiveness. While it can compensate for misalignments, backlash may introduce delays and reduce the overall performance of the gear motor. Designers manage backlash through tight manufacturing tolerances, preload techniques, anti-backlash gears, and backlash compensation methods. The management of backlash depends on the specific application requirements, considering factors such as positioning accuracy, dynamic response, and load characteristics.

What is a gear motor, and how does it combine the functions of gears and a motor?

A gear motor is a type of motor that incorporates gears into its design to combine the functions of gears and a motor. It consists of a motor, which provides the mechanical power, and a set of gears, which transmit and modify this power to achieve specific output characteristics. Here’s a detailed explanation of what a gear motor is and how it combines the functions of gears and a motor:

A gear motor typically consists of two main components: the motor and the gear system. The motor is responsible for converting electrical energy into mechanical energy, generating rotational motion. The gear system, on the other hand, consists of multiple gears with different sizes and tooth configurations. These gears are meshed together in a specific arrangement to transmit and modify the output torque and speed of the motor.

The gears in a gear motor serve several functions:

1. Torque Amplification:

One of the primary functions of the gear system in a gear motor is to amplify the torque output of the motor. By using gears with different sizes, the input torque can be effectively multiplied or reduced. This allows the gear motor to provide higher torque at lower speeds or lower torque at higher speeds, depending on the gear arrangement. This torque amplification is beneficial in applications where high torque is required, such as in heavy machinery or vehicles.

2. Speed Reduction or Increase:

The gear system in a gear motor can also be used to reduce or increase the rotational speed of the motor output. By utilizing gears with different numbers of teeth, the gear ratio can be adjusted to achieve the desired speed output. For example, a gear motor with a higher gear ratio will output lower speed but higher torque, whereas a gear motor with a lower gear ratio will output higher speed but lower torque. This speed control capability allows for precise matching of motor output to the requirements of specific applications.

3. Directional Control:

Gears in a gear motor can be used to control the direction of rotation of the motor output shaft. By employing different combinations of gears, such as spur gears, bevel gears, or worm gears, the rotational direction can be changed. This directional control is crucial in applications where bidirectional movement is required, such as in conveyor systems or robotic arms.

4. Load Distribution:

The gear system in a gear motor helps distribute the load evenly across multiple gears, which reduces the stress on individual gears and increases the overall durability and lifespan of the motor. By sharing the load among multiple gears, the gear motor can handle higher torque applications without putting excessive strain on any particular gear. This load distribution capability is especially important in heavy-duty applications that require continuous operation under demanding conditions.

By combining the functions of gears and a motor, gear motors offer several advantages. They provide torque amplification, speed control, directional control, and load distribution capabilities, making them suitable for various applications that require precise and controlled mechanical power. Gear motors are commonly used in industries such as robotics, automotive, manufacturing, and automation, where reliable and efficient power transmission is essential.

editor by CX 2024-05-16

China Professional Combination Gear Motor with Parallel Shaft F Type and Coaxial R Type Connect to a Variable Speed Motor vacuum pump ac

Product Description

Parallel Shaft Helical Bevel Gear Motor (F Type)

|

Input Configurations |

Motor mounted |

| IEC B5/B14 Motor Flange (AM Flange) | |

| Servo Motor Flange (AQA Flange) | |

| Shaft Input (AD connection) | |

|

Output Configurations

|

CHINAMFG output shaft |

|

CHINAMFG output shaft with flange |

|

|

Hollow output shaft |

|

|

Hollow output shaft and flange |

|

|

Variants of the Parallel Shaft Helical Gear Unit Series F / FF / FA / FAF |

Foot- or flange-mounted |

|

B5 or B14 flange-mounted |

|

|

CHINAMFG shaft or hollow shaft |

|

|

Hollow shaft with key connection, shrink disk, splined hollow shaft, or Torque Arm |

Main Feature

Slim design for limited installation space without having to compromise on the performance, And what applies to many of our gear units: longer operating lives and wear-free gearing with a high fatigue strength.

Specification

|

Model |

Shaft Dia. mm |

Horizontal Center Height mm |

External Flange Dia. Mm |

Power Kw |

Ratio i |

Nominal Torque Nm |

|

|

CHINAMFG Shaft |

Hollow Shaft |

||||||

|

F/FF/FA/FAF37 |

ф25 |

ф30 |

70 |

160 |

0.12-3 |

4-138 |

180 |

|

F/FF/FA/FAF47 |

ф35 |

ф35 |

80 |

200 |

0.12-5.5 |

4-175 |

360 |

|

F/FF/FA/FAF57 |

ф35 |

ф40 |

100 |

250 |

0.18-7.5 |

4-197 |

420 |

|

F/FF/FA/FAF67 |

ф40 |

ф40 |

100 |

250 |

0.37-7.5 |

4-197 |

700 |

|

F/FF/FA/FAF77 |

ф50 |

ф50 |

120 |

300 |

0.75-11 |

4-197 |

1350 |

|

F/FF/FA/FAF87 |

ф60 |

ф60 |

155 |

350 |

1.5-22 |

4-193 |

2500 |

|

F/FF/FA/FAF97 |

ф70 |

ф70 |

180 |

450 |

2.2-30 |

4-203 |

3700 |

|

F/FF/FA/FAF107 |

ф90 |

ф90 |

200 |

450 |

3-45 |

4-205 |

6500 |

|

F/FF/FA/FAF127 |

ф110 |

ф100 |

240 |

550 |

5.5-90 |

4-202 |

10000 |

|

F/FF/FA/FAF157 |

ф120 |

ф120 |

270 |

660 |

11-160 |

4-190 |

18000 |

Company Profile

Packing

Scenarioes

FAQ

Q1: I want to buy your products, how can I pay?

A: You can pay via T/T(30%+70%), L/C ,D/P etc.

Q2: How can you guarantee the quality?

A: One year’s warranty against B/L date. If you meet with quality problem, please send us pictures or video to check, we promise to send spare parts or new products to replace. Our guarantee not include inappropriate operation or wrong specification selection.

Q3: How we select models and specifications?

A: You can email us the series code (for example: RC series helical gearbox) as well as requirement details, such as motor power,output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings,it is nice.

Q4: If we don’t find what we want on your website, what should we do?

A: We offer 3 options:

1, You can email us the pictures, drawings or descriptions details. We will try to design your products on the basis of our

standard models.

2, Our R&D department is professional for OEM/ODM products by drawing/samples, you can send us samples, we do customized design for your bulk purchasing.

3, We can develop new products if they have good market. We have already developed many items for special using successful, such as special gearbox for agitator, cement conveyor, shoes machines and so on.

Q5: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q6: How about your product delivery time?

A: Normally for 20’container, it takes 25-30 workdays for RV series worm gearbox, 35-40 workdays for helical gearmotors.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Foot/Flange Mounted |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Double-Step |

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about gear motors and their applications?

Individuals seeking to learn more about gear motors and their applications have access to various reliable resources that provide valuable information and insights. Here are some sources where individuals can find reliable information about gear motors:

1. Manufacturer Websites:

Manufacturer websites are a primary source of information about gear motors. Gear motor manufacturers often provide detailed product specifications, application guides, technical documentation, and educational materials on their websites. These resources offer insights into different gear motor types, features, performance characteristics, and application considerations. Manufacturer websites are a reliable and convenient starting point for learning about gear motors.

2. Industry Associations and Organizations:

Industry associations and organizations related to mechanical engineering, automation, and motion control often have resources and publications dedicated to gear motors. These organizations provide technical articles, whitepapers, industry standards, and guidelines related to gear motor design, selection, and application. Examples of such associations include the American Gear Manufacturers Association (AGMA), International Electrotechnical Commission (IEC), and Institute of Electrical and Electronics Engineers (IEEE).

3. Technical Publications and Journals:

Technical publications and journals focused on engineering, robotics, and motion control are valuable sources of in-depth knowledge about gear motors. Publications like IEEE Transactions on Industrial Electronics, Mechanical Engineering magazine, or Motion System Design magazine often feature articles, case studies, and research papers on gear motor technology, advancements, and applications. These publications provide authoritative and up-to-date information from industry experts and researchers.

4. Online Forums and Communities:

Online forums and communities dedicated to engineering, robotics, and automation can be excellent resources for discussions, insights, and practical experiences related to gear motors. Websites like Stack Exchange, engineering-focused subreddits, or specialized forums provide platforms for individuals to ask questions, share knowledge, and engage in discussions with professionals and enthusiasts in the field. Participating in these communities allows individuals to learn from real-world experiences and gain practical insights.

5. Educational Institutions and Courses:

Technical colleges, universities, and vocational training centers often offer courses or programs in mechanical engineering, mechatronics, or automation that cover gear motor fundamentals and applications. These educational institutions provide comprehensive curricula, textbooks, and lecture materials that can serve as reliable resources for individuals interested in learning about gear motors. Additionally, online learning platforms like Coursera, Udemy, or LinkedIn Learning offer courses on topics related to gear motors and motion control.

6. Trade Shows and Exhibitions:

Attending trade shows, exhibitions, and industry conferences related to automation, robotics, or motion control provides opportunities to learn about the latest advancements in gear motor technology. These events often feature product demonstrations, technical presentations, and expert panels where individuals can interact with gear motor manufacturers, industry experts, and other professionals. It’s a great way to stay updated on the latest trends, innovations, and applications of gear motors.

When seeking reliable resources, it’s important to consider the credibility of the source, the expertise of the authors, and the relevance to the specific area of interest. By leveraging these resources, individuals can gain a comprehensive understanding of gear motors and their applications, from basic principles to advanced topics, enabling them to make informed decisions and effectively utilize gear motors in their projects or applications.

Can you explain the role of backlash in gear motors and how it’s managed in design?

Backlash plays a significant role in gear motors and is an important consideration in their design and operation. Backlash refers to the slight clearance or play between the teeth of gears in a gear system. It affects the precision, accuracy, and responsiveness of the gear motor. Here’s an explanation of the role of backlash in gear motors and how it is managed in design:

1. Role of Backlash:

Backlash in gear motors can have both positive and negative effects:

- Compensation for Misalignment: Backlash can help compensate for minor misalignments between gears, shafts, or the load. It allows a small amount of movement before engaging the next set of teeth, reducing the risk of damage due to misalignment. This can be particularly beneficial in applications where precise alignment is challenging or subject to variations.

- Negative Impact on Accuracy and Responsiveness: Backlash can introduce a delay or “dead zone” in the motion transmission. When changing the direction of rotation or reversing the load, the gear teeth must first overcome the clearance or play before engaging in the opposite direction. This delay can reduce the overall accuracy, responsiveness, and repeatability of the gear motor, especially in applications that require precise positioning or rapid changes in direction or speed.

2. Managing Backlash in Design:

Designers employ various techniques to manage and minimize backlash in gear motors:

- Tight Manufacturing Tolerances: Proper manufacturing techniques and tight tolerances can help minimize backlash. Precision machining and quality control during the production of gears and gear components ensure closer tolerances, reducing the amount of play between gear teeth.

- Preload or Pre-tensioning: Applying a preload or pre-tensioning force to the gear system can help reduce backlash. This technique involves introducing an initial force or tension that eliminates the clearance between gear teeth. It ensures immediate contact and engagement of the gear teeth, minimizing the dead zone and improving the overall responsiveness and accuracy of the gear motor.

- Anti-Backlash Gears: Anti-backlash gears are designed specifically to minimize or eliminate backlash. They typically feature modifications to the gear tooth profile, such as modified tooth shapes or special tooth arrangements, to reduce clearance. Anti-backlash gears can be used in gear motor designs to improve precision and minimize the effects of backlash.

- Backlash Compensation: In some cases, backlash compensation techniques can be employed. These techniques involve monitoring the position or movement of the load and applying control algorithms to compensate for the backlash. By accounting for the clearance and adjusting the control signals accordingly, the effects of backlash can be mitigated, improving accuracy and responsiveness.

3. Application-Specific Considerations:

The management of backlash in gear motors should be tailored to the specific application requirements:

- Positioning Accuracy: Applications that require precise positioning, such as robotics or CNC machines, may require tighter backlash control to ensure accurate and repeatable movements.

- Dynamic Response: Applications that involve rapid changes in direction or speed, such as high-speed automation or servo control systems, may require reduced backlash to maintain responsiveness and minimize overshoot or lag.

- Load Characteristics: The nature of the load and its impact on the gear system should be considered. Heavy loads or applications with significant inertial forces may require additional backlash management techniques to maintain stability and accuracy.

In summary, backlash in gear motors can affect precision, accuracy, and responsiveness. While it can compensate for misalignments, backlash may introduce delays and reduce the overall performance of the gear motor. Designers manage backlash through tight manufacturing tolerances, preload techniques, anti-backlash gears, and backlash compensation methods. The management of backlash depends on the specific application requirements, considering factors such as positioning accuracy, dynamic response, and load characteristics.

Can you explain the advantages of using gear motors in various mechanical systems?

Gear motors offer several advantages when utilized in various mechanical systems. Their unique characteristics make them well-suited for applications that require controlled power transmission, precise speed control, and torque amplification. Here’s a detailed explanation of the advantages of using gear motors:

1. Torque Amplification:

One of the key advantages of gear motors is their ability to amplify torque. By using different gear ratios, gear motors can increase or decrease the output torque from the motor. This torque amplification is crucial in applications that require high torque output, such as lifting heavy loads or operating machinery with high resistance. Gear motors allow for efficient power transmission, enabling the system to handle demanding tasks effectively.